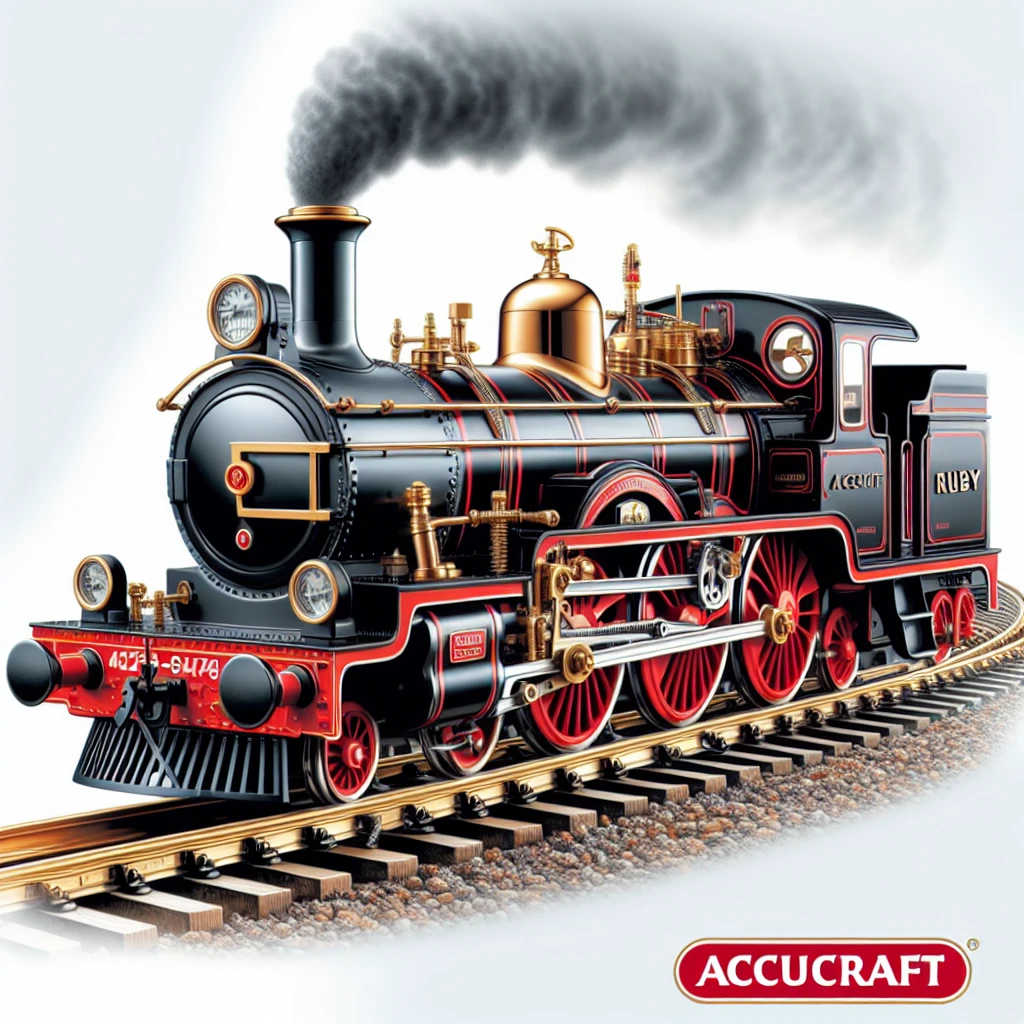

If you’re a model train enthusiast, you understand the importance of precision. The Accucraft Ruby, a popular choice among U.S. hobbyists, is no exception when it comes to mechanical accuracy. Setting the timing on your Accucraft Ruby is a crucial task to ensure smooth operation and optimal performance. This blog post will guide you through the process, offering practical tips and insights that how to set the timing on a accucraft ruby. Whether you’re a seasoned enthusiast or a newcomer to model railroads, you’ll find valuable information here to enhance your hobby.

Getting to Know Your Accucraft Ruby

Before you begin setting the timing, it’s essential to familiarize yourself with your Accucraft Ruby’s components. This model is known for its robust build and reliable performance, making it a favorite among steam enthusiasts in the USA.

The Ruby is a 1/19 scale model, featuring a live steam engine powered by butane gas. It’s equipped with a double-action cylinder and slide valve, controlled by the aforementioned Walschaerts valve gear. Knowing these details will help you understand how timing adjustments affect your locomotive.

Accucraft Ruby models are praised for their straightforward design, which makes them an excellent choice for beginners. They provide an excellent platform for learning about steam engine mechanics and timing without the complexity of larger models.

Understanding Accucraft Ruby Timing

Accucraft Ruby is a small live steam locomotive, prized for its intricate design and operational capabilities. Timing, in this context, refers to the synchronization of the piston’s movement with the opening of the steam ports. Correct timing ensures that the steam pressure is optimally utilized, leading to efficient and smooth operation.

Setting the timing correctly can significantly impact your locomotive’s performance. Poor timing can lead to inefficient steam usage, jerky movements, and even mechanical wear. Understanding timing basics is your first step toward mastering your Accucraft Ruby.

The Importance of Proper Timing

Timing is to a steam locomotive what tuning is to a musical instrument. It’s all about harmony. Proper timing ensures that your model train runs smoothly and efficiently, with minimal wear and tear. It can also prolong the life of your locomotive by preventing unnecessary strain on mechanical components.

Correct timing translates to better performance, meaning your Ruby will handle gradients and curves more effectively. It’s not just about performance; it’s about maintaining the longevity and aesthetic appeal of your model. A well-timed locomotive is a joy to watch as it glides effortlessly along the tracks.

How to Set the Timing on a Accucraft Ruby?

1. Tools You’ll Need for Timing

To set the timing on your Accucraft Ruby, you’ll need a few essential tools. Having the right equipment will make the process smoother and more efficient, allowing you to focus on the details that matter.

First, you’ll need a small set of screwdrivers for adjusting the screws and bolts on your Ruby. A set of feeler gauges can help measure the gap between components, ensuring precise adjustments. Finally, a timing gauge or protractor can be useful for measuring valve movement angles.

Investing in quality tools is always a good idea. It ensures accuracy and longevity, both of which are crucial when working with steam engines. If you’re just starting, consider purchasing a beginner’s toolkit that includes all these essentials.

2. Preparing Your Ruby for Timing Adjustments

Before making any adjustments, it’s crucial to prepare your Ruby properly. This involves inspecting and cleaning the locomotive, ensuring all parts are in good condition and free of debris.

Start by giving your Ruby a thorough cleaning. Use a soft brush to remove dust and dirt, paying close attention to the valve gear and pistons. Cleaning not only improves performance but also prevents wear and tear on moving parts.

Next, inspect the valve gear for any signs of damage or wear. Look for loose screws or bolts and tighten them as needed. This preventative maintenance step ensures your Ruby is in optimal condition for timing adjustments.

3. Setting the Valve Gear to Neutral

The first step in adjusting the timing is setting the valve gear to neutral. This position allows the steam to flow into the cylinders without moving the pistons, making it easier to observe and adjust valve movement.

To set the valve gear to neutral, use your screwdriver to loosen the fixing bolts on the valve gear. Gently slide the gear into the neutral position, ensuring it’s perfectly aligned. Tighten the bolts to secure the gear in place.

Setting the valve gear to neutral is akin to placing a car in park. It stabilizes the engine, allowing you to focus on the details of the timing without interference from other moving parts.

4. Aligning the Valve with the Piston

Once the valve gear is in neutral, it’s time to align the valve with the piston. This step ensures that steam enters and exits the cylinders at the correct times, optimizing power and efficiency.

Begin by rotating the driving wheels slowly, observing the movement of the valve and piston. Use your timing gauge to measure the angle of valve movement, making adjustments as needed. The goal is to have the valve open just as the piston reaches the end of its stroke.

Alignment can be a bit tricky, but with practice, you’ll develop a feel for it. Remember, precision is key. Even minor misalignments can affect your Ruby’s performance significantly.

5. Adjusting the Eccentric Rod

The eccentric rod is a crucial component in the timing system. It connects the valve gear to the driving wheels, translating wheel movement into valve action. Adjusting this rod is necessary for fine-tuning the timing.

To adjust the eccentric rod, loosen the fixing screws and slide the rod to achieve the desired alignment. Use your feeler gauges to check the gap between the rod and the driving wheel, ensuring it’s even on both sides.

Getting the eccentric rod just right can take a bit of trial and error. Don’t rush the process. Taking your time ensures you achieve the perfect balance between valve movement and wheel rotation.

6. Testing Your Adjustments

After making your adjustments, it’s essential to test your Ruby to ensure everything is set correctly. Testing allows you to observe the locomotive’s performance and identify any further tweaks needed.

Fire up your Ruby and place it on a test track. Observe its movement, paying attention to any irregularities in speed or power. Listen for unusual sounds, which can indicate misalignment or timing issues.

Testing is a valuable learning opportunity. It provides immediate feedback on your adjustments, helping you refine your skills and improve your Ruby’s performance.

Common Timing Issues and Solutions

Even with careful adjustments, you may encounter common timing issues. Knowing how to identify and address these problems will help you maintain your Ruby’s performance.

One common issue is steam leakage due to incorrect valve alignment. If you notice a drop in power, check the valve position and adjust as needed. Another issue is uneven wheel rotation, often caused by misaligned eccentric rods. Realign the rods to solve this problem.

Understanding these common issues equips you with the knowledge to troubleshoot and resolve them quickly, keeping your Ruby in top shape.

Tips for Maintaining Your Ruby

Regular maintenance is key to keeping your Accucraft Ruby running smoothly. By incorporating these tips into your routine, you’ll prolong the life of your steam engine and ensure it performs at its best.

First, establish a cleaning schedule. Regular cleaning prevents buildup of dirt and debris, which can affect performance. Second, inspect the valve gear and pistons regularly, tightening any loose parts. This prevents wear and tear and keeps your Ruby in good working order.

Finally, lubricate moving parts with high-quality steam oil. This reduces friction and prevents damage, keeping your Ruby running smoothly for years to come.

Exploring Advanced Timing Techniques

Once you’re comfortable with basic timing adjustments, consider exploring advanced techniques. These methods allow for greater precision and performance, taking your Ruby to the next level.

One advanced technique is adjusting the cut-off, which controls how long steam enters the cylinder during each stroke. Fine-tuning the cut-off can improve efficiency and power. Another technique is balancing the valve gear, ensuring even distribution of steam to both cylinders.

Advanced techniques require practice and patience, but the rewards are worth it. Mastering these methods gives you greater control over your Ruby’s performance, enhancing your enjoyment of the hobby.

Conclusion

Setting the timing on your Accucraft Ruby is a rewarding process that enhances your steam engine’s performance and your enjoyment of the hobby. By following this guide, you’ll gain the skills and confidence needed to master your Ruby’s timing, ensuring it runs smoothly and efficiently.

Remember, practice makes perfect. The more you work with your Ruby, the better you’ll become at making precise adjustments. Don’t be afraid to experiment and explore new techniques, as this will deepen your understanding and appreciation for these fascinating machines.

For those looking to expand their knowledge further, consider exploring additional resources and connecting with fellow enthusiasts. The world of steam engines offers endless opportunities for learning and discovery, and there’s always more to explore.

Leave a Reply